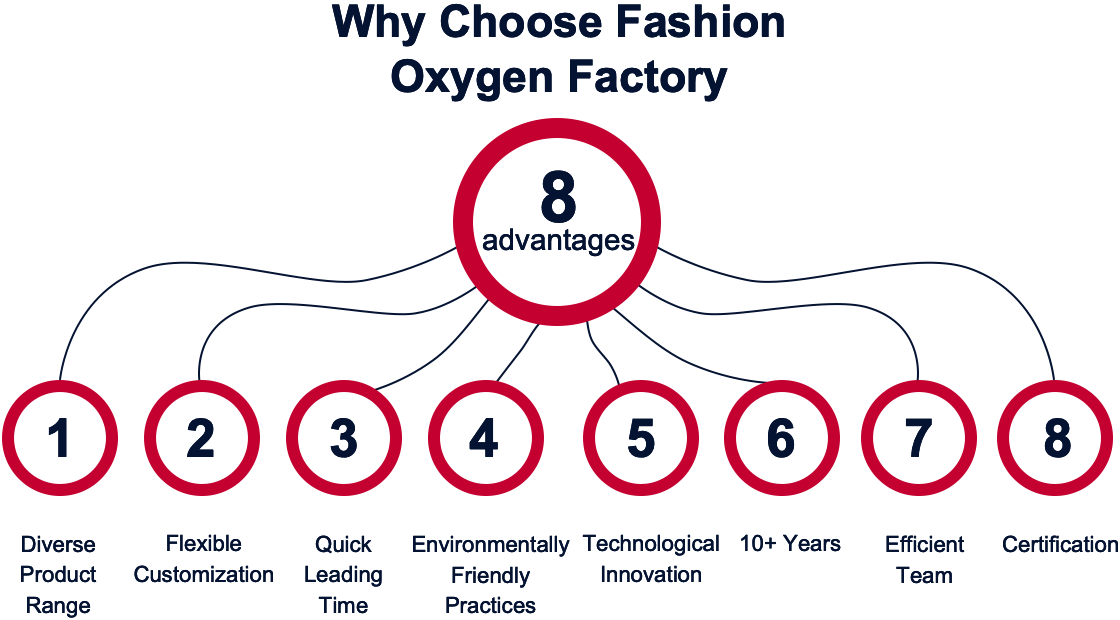

Diverse Product Range:

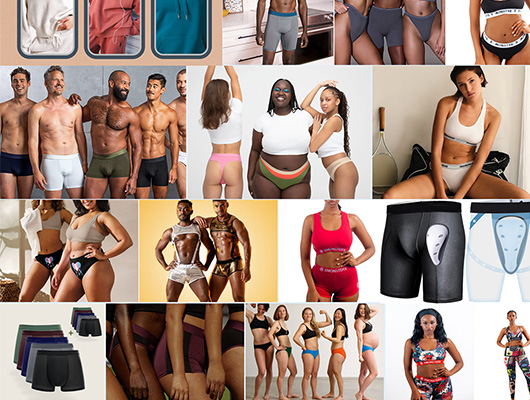

Capable of producingvarious types, includingmen’s underwear, women’s underwear, children's underwear, sports underwear, leggings, t-shirts, sweatshirts, and more, covering a wide consumer base.

Capable of producingvarious types, includingmen’s underwear, women’s underwear, children's underwear, sports underwear, leggings, t-shirts, sweatshirts, and more, covering a wide consumer base.

Ability to provide personalized design and production based on customer needs, catering to diverse market demands and consumer preferences. has alow MOQ, accepts1-piece customization, and partners with multiple processing facilities to effectivelymeet both small and large underwear order demands.

The fastest production can be done within 3 days after the customer places an order. This capability not only satisfies consumer expectations for quick delivery but also positions the brand favorably in a competitive marketplace. Additionally, if the agreed delivery deadline is exceeded, a penalty of $100 or 1% of the order amount will be imposed each week.

Many modern underwear factories are committed to sustainable development by using eco-friendly materials and processes, such as those certified by the Global Recycled Standard (GRS), to reduce environmental impact.

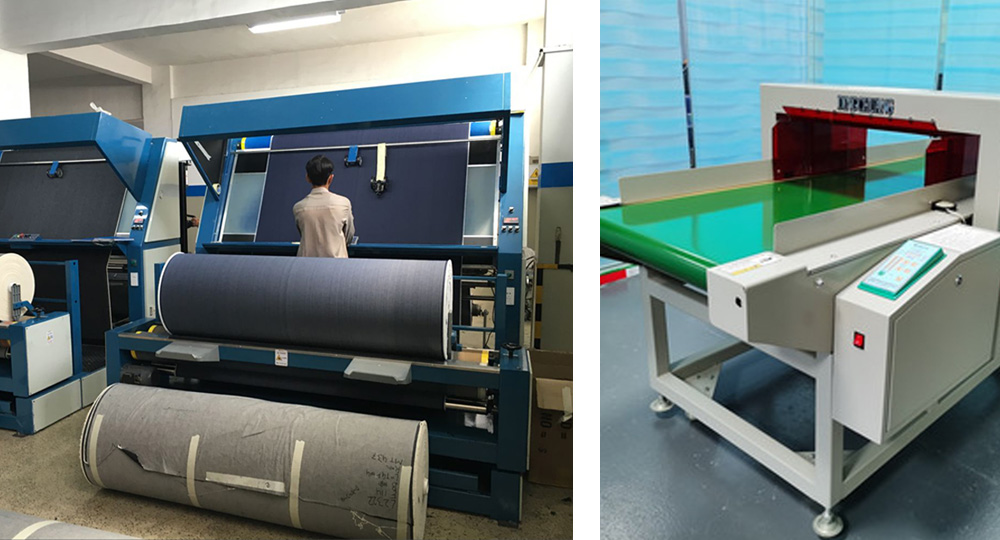

Continuous investment inadvanced production technologies and equipmentimproves efficiency and product quality, allowi ng the factory to adapt to market changes

focused on underwear manufacturing, the factory hasover 10 years of extensive industry experience and expertise, ensuring high-quality products.

ensure that products meet high standards in design, production, and quality control.

Equipped with the latest design software and technology, our designers can transform their ideas into reality with high efficiency. They can create detailed 2D and 3D models, which allow for precise visualization of the final products. This not only helps in the design process but also i communicating with clients, as you can clearly see how the finished clothing will look. Moreover, these tools enable us to make quick modifications and improvements during the design stage, reducing the time - to - market for new designs.

We understand that different clients have different needs. Our R & D team has the ability to provide customized design services. Whether it's a unique logo, a specific color combination, or a special pattern, we can tailor -make designs according to your requirements.

In summary, our R & D team has the design capabilities to create fashionable, market - relevant, customized, and sustainable clothing. We are confident that our designs can meet your expectations and help you succeed in the international clothing business.

For clients who are just starting their own underwear brands, we have dedicated professionals who assist in identifying the samples that best meet their needs from the client's perspective. Our team ensures that we capture the essential requirements and preferences, facilitating a tailored approach to product development.

Our fast sample making process is optimized for efficiency without compromising quality. From the moment we receive your design specifications, our skilled team works diligently to produce samples within just a few days. This swift turnaround allows you to evaluate designs and make necessary adjustments promptly, keeping your project on track.

Our fast sample making service is not limited to standard designs. We welcome customization requests to meet your unique specifications. Whether it involves special sizes, unique design elements, or specific functional features, our team is dedicated to ensuring that the final sample aligns with your expectations.

Equipped with advanced computer-aided design (CAD) technology, our designers can translate your creative concepts into precise technical drawings. This accuracy significantly reduces the chances of errors during production, ensuring that every sample closely matches your vision. Our commitment is to deliver samples that reflect your design intentions perfectly.

We recognize the importance of deadlines in your business operations. Therefore, we commit to delivering samples on time as agreed. If unforeseen circumstances arise, we will communicate with you promptly to keep you informed of any changes in the timeline.

Quality is our top priority. Each sample undergoes rigorous inspection before delivery to ensure it meets our high standards and yours. Our experienced quality control team meticulously checks every detail, from stitching to fit, guaranteeing that the samples are of premium quality.

Over the years, we have established stable cooperative relationships with more than 57 high-quality fabric suppliers, including those specializing in fabrics, printing, and waistbands. Our professional procurement team strictly selects materials according to international quality standards. Before entering the factory, each batch of materials undergoes rigorous quality inspections to ensure that only the best materials are used in production. Notably, over 70% of our suppliers have collaborated with us for over 10 years, which provides a strong guarantee of quality. We prioritize quality control right from the source to ensure that our products meet the highest standards.

Our design team consists of experienced designers who are well-versed in international fashion trends. They work closely with clients to understand their specific requirements and design unique clothing styles. Once the design is finalized, our pattern-making experts, each with over 10 years of industry experience, use advanced CAD software and their rich expertise to create precise and detailed patterns. These pattern makers have worked with renowned clothing brands such as NIKE, Supreme, etc. to ensure high-quality production. The patterns they create serve as the foundation for the subsequent production process, ensuring the perfect fit and shape of the clothing.

We utilize state-of-the-art cutting equipment, including advanced laser infrared sensing automatic cutting machines. Our skilled operators input the patterns into computer-controlled cutting machines, which can accurately cut the fabric using high-precision lasers or blades, minimizing errors. The incorporation of laser infrared sensing technology enhances the accuracy and efficiency of the cutting process, ensuring optimal fabric utilization and significantly reducing waste. During this process, we pay close attention to fabric utilization efficiency to minimize waste as much as possible. The cut fabric pieces are then sorted and labeled for easy identification during the sewing process.

Our sewing workshop is staffed by over 45 highly trained and skilled sewing workers. They use professional-grade sewing machines and advanced sewing techniques, including equipment from Yamato in Japan, such as four-needle six-thread machines, overlock machines, automatic waist cutting machines, and more. Each sewing process follows strict quality control procedures. From stitching the main body of the underwear to attaching accessories, every step is carried out with meticulous care. Additionally, we have a comprehensive quality inspection system in place during the sewing process to ensure that any potential quality issues are detected and resolved in a timely manner.

Quality inspection is a key part of our production process. We have a professional quality inspection team consisting of over 7 dedicated inspectors who conduct inspections at multiple stages. During the production process, we carry out random inspections to check the quality of sewing, fabric, and accessories. After the completion of the entire production process, 100% of the products undergo a comprehensive inspection in accordance with AQL 2.0 standards. We use international-standard inspection tools and methods to ensure that each product meets the highest quality requirements. Only products that pass the inspection are allowed to enter the packaging process.

After passing the quality inspection, the clothing items enter the ironing process. Our ironing staff are experts in handling different types of fabrics and clothing styles. They use specialized steam irons and pressing machines that are adjusted according to the specific fabric requirements. The purpose of ironing is not only to make the clothes look smooth and presentable but also to enhance the shape and fit of the garment.

Finally, the ironed clothing is prepared for packaging. We use environmentally friendly and high - quality packaging materials to protect the products during transportation. The packaging design also takes into account factors such as brand image and product protection. Once packaged, the products are prepared for timely delivery according to the agreed - upon shipping terms with our clients.

In the pattern - making process, our experienced designers and technicians use advanced software and tools. They double - check the patterns for accuracy in size, shape, and seam allowances. During cutting, our well - trained workers operate high - precision cutting machines. We have a system to ensure that the cutting is precise and there is minimal waste. Regular checks are made to confirm that the cut pieces match the patterns exactly.

Rigorous Supplier Evaluation:We carefully select our raw material suppliers based on their reliability, quality standards, and compliance with industry regulations. We conduct regular audits to ensure they meet our stringent criteria.

Long-term Partnerships:We build strong, long-lasting relationships with our suppliers, fostering collaboration and transparency. This ensures a consistent supply of high-quality materials while allowing us to respond quickly to changes in demand.

Real-time Tracking:We utilize advanced inventory management software to monitor stock levels in real-time. This helps us maintain optimal inventory levels, reducing waste and ensuring we have sufficient materials on hand to meet customer orders.

Just-in-Time (JIT) Approach:By implementing a JIT inventory strategy, we minimize excess stock and reduce storage costs. This approach also allows us to be more agile in responding to market trends and customer requirements.

Flexible Production Scheduling:Our production planning team employs flexible scheduling techniques to adapt to varying order volumes and timelines. This flexibility enables us to manage peak seasons effectively without compromising quality.

Capacity Utilization:We continuously monitor production capacity and workflow efficiency, making adjustments as necessary to optimize output while maintaining high-quality standards.

Streamlined Logistics Operations:We partner with reliable logistics providers, including DHL, FedEx, and COSCO, to ensure timely delivery of both raw materials and finished products. Our logistics team works diligently to optimize shipping routes and reduce transit times.

Customs Compliance:We have a thorough understanding of international shipping regulations and customs procedures, which helps us avoid delays and ensure smooth cross-border transactions.

Integrated Quality Assurance:Quality control measures are integrated at every stage of the supply chain, from raw material sourcing to final product inspections. This holistic approach ensures that we consistently meet and exceed customer expectations.

Feedback Loop:We maintain an open line of communication with our suppliers and customers, encouraging feedback to identify areas for improvement and enhance overall product quality.

Regular Reviews and Assessments:We conduct regular reviews of our supply chain processes to identify inefficiencies and areas for improvement. This commitment to continuous improvement allows us to enhance our operations and provide better service to our customers.

Training and Development:Our team participates in ongoing training programs to stay updated on industry best practices and emerging technologies, ensuring our supply chain management remains competitive and effective.